Fitting instructions thru axle adapter universal TOUT TERRAIN

! WARNING !

The towing bike must be approved for towing a trailer. Riding the trailer with a towing bike that has not been approved by the manufacturer can lead to frame breakage or other material problems. This can result in accidents with life-threatening injuries.

If you are not sure how to fit our thru axle with adapter correctly, please contact a specialist workshop.

Our thru axle with adapter must be fitted correctly. An incorrectly fitted thru axle with adapter can come loose while riding and lead to accidents with life-threatening injuries.

You should definitely bear this in mind:

- Our thru axles with adapter are only approved for bicycles and pedelecs (max. 25 km/h), not for S-pedelecs or e-bikes from 25 km/h!

- We would like to point out to all dealers and end users that they themselves are responsible for the entire bicycle trailer system and its correct functioning in terms of product liability!

- It is your responsibility to determine the correct thread size and installation length [mm] of your current thru axle on the wheel. Do not attempt to fit our thru axle with interchangeable system in a different thread size in your rear wheel hub. An incorrect thread size can damage your bike. If you are unsure about the correct thread size and installation length, please contact us by email or phone and we will be happy to help you.

- cannot be used with bikes made of carbon or with carbon dropouts and carbon rear triangle!

- Regularly check the correct torque setting and that all components are free of play before using your bike in trailer mode!

- If you do not have a calibrated torque wrench for fitting our thru axle with adapter, contact a specialist workshop.

FOR ASSEMBLY

IMPORTANT: Always mount the trailer on the left-hand side in the direction of travel!

We recommend lubricating the thread of the thru axle with appropriate assembly paste before use to prevent friction, contact corrosion and wear.

The following Dynamic Bike Care products are ideal for this purpose.

To tighten the thru axle, you will need a torque wrench with a 6 mm hexagon socket.

Please refer to your bike's operating instructions for the tightening torque, usually 12-15 Nm for steel and aluminum frames.

You can then attach our universal adapter to the threaded bolt of the thru axle, but first remove the screw and the two wedge lock washers on the adapter and slide the Nord Lock wedge lock washer with the inner diameter(ø13.0mm) onto the protruding threaded bolt of the thru axle.

To tighten the adapter you will need an open-end wrench SW17mm, or if you have a torque wrench with a long 17mm socket, even better.

Please ensure that the tightening torque when tightening the adapter is not higher than that of the previously tightened thru axle.(12-15Nm)

To be on the safe side, you can counter-lock the quick-release axle from the other side with an Allen key SW6mm on the head of the axle to prevent possible transfer of the tightening torque when tightening the adapter.

Now you can attach your clutch to the adapter, the wedge lock washer with the larger inner diameter(ø10.7mm) is always behind the clutch, the wedge lock washer with the smaller inner diameter(ø8.7mm) comes in front of the clutch behind the M8 x 16mm bolt, virtually in a sandwich.

To tighten the clutch properly (the engagement of the teeth of the wedge lock washers must be ensured), we recommend using a ring wrench SW13mm or, even better, a ratchet with a 13mm socket.

When tightening the screw(M8 x 16), make sure that the tightening torque is not transferred to the already tightened quick-release axle and the adapter.

You can also tighten the adapter using a 17 mm open-end wrench (to counter it).

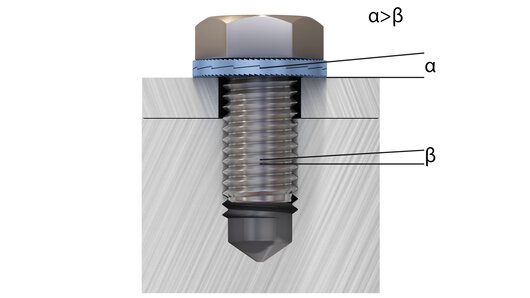

The nuts and bolts of our clutch connection are the wedge lock washers from Nord-Lock, here you can see how they work.